- Products

- Compressors & Assemblies

- Condensing units

- Outdoor units

- Fully-hermetic

- CO2

- Panasonic CO2 condensing unit Invert. OCU-CR1000VF8 R744 400V

Panasonic CO2 condensing unit Invert. OCU-CR1000VF8 R744 400V

Description

Panasonic offers an environmentally friendly and reliable system solution for commercial cooling and freezing applications. The reasons for developing the CO2 condensing units are clear: the ability for high energy savings, operational safety and reliability for our customers and, last but not ...

Panasonic offers an environmentally friendly and reliable system solution for commercial cooling and freezing applications. The reasons for developing the CO2 condensing units are clear: the ability for high energy savings, operational safety and reliability for our customers and, last but not least, our environment. CO2 technology makes it easier to meet EU climate protection goals which require all fluorinated greenhouse gases (F-gases) to eventually be fully replaced by alternative refrigerants. Alternatively, different refrigerant mixes can be used. However, the sheer number of these makes refrigerant handling difficult and problematic. Instead, you should choose a solid, tried-and-tested, environmentally friendly solution from Panasonic. Panasonic recommends CO2 (R744) - the best choice for a natural refrigerant. The CO2 condensing units from Panasonic with transcritical process control guarantee long-lasting, safe, reliable and energy saving operation.

Panasonic CO2 systems, 4 kW and 15 kW

Food storage requires high standards to be met in retail shops and supermarkets. High-quality and reliable systems are the key to success. As a comprehensive solution, Panasonic offers a system comprising the condensing unit, a control panel with pre-programmed controller, expansion valve and all necessary sensors.

The easy to install system from Panasonic includes all key components

The system is equally suitable for retail stores and supermarket chains. Thanks to the low weight of just 70 kg, no expensive base is required. The system is delivered ready to install and use. The customer only needs to provide the evaporator, safety valve and piping. In order to make installation easier, all parts of the system are delivered as a single package. The control panel for the system features a pre-programmed controller that is specially designed for controlling and monitoring cooling locations and actuates the electronic expansion valve. The combination of high-quality components and precise control of the modulated electronic expansion vale guarantees an extremely stable and energy-efficient system. Stable superheat and pressure values are key to ensuring low energy consumption and high performance throughout the key. The system is compatible with the building control systems commonly used in Europe.

One system - two application areas

The transcritical CO2 condensing unit from Panasonic features low energy consumption and low CO2 output. The compact system can be used for freezing applications as well as normal temperatures. When setting up, just one parameter needs setting - the target temperature: In order to prepare the system for use, simply rotate the control knob to one of the four target temperature ranges for the desired application.

Features

Benefits of CO2 as a refrigerant:

- Non-toxic, non-flammable

- Global warming potential (GWP100) = 1

- Ozone depletion potential (ODP) = 0

- High volumetric cooling capacity

Benefits of the CO2 condensing units from Panasonic:

- Energy saving

- Simple installation

- Low noise

- Low weight, compact design

- Minimal ...

Benefits of CO2 as a refrigerant:

- Non-toxic, non-flammable

- Global warming potential (GWP100) = 1

- Ozone depletion potential (ODP) = 0

- High volumetric cooling capacity

Benefits of the CO2 condensing units from Panasonic:

- Energy saving

- Simple installation

- Low noise

- Low weight, compact design

- Minimal refrigerant required

- Low installation costs

- Low maintenance costs

- Extensive prefabrication for industrial quality

The new condensing units from Panasonic with environmentally friendly refrigerant CO2 (R744) have been specially developed for commercial use in food shops, supermarkets and petrol stations.

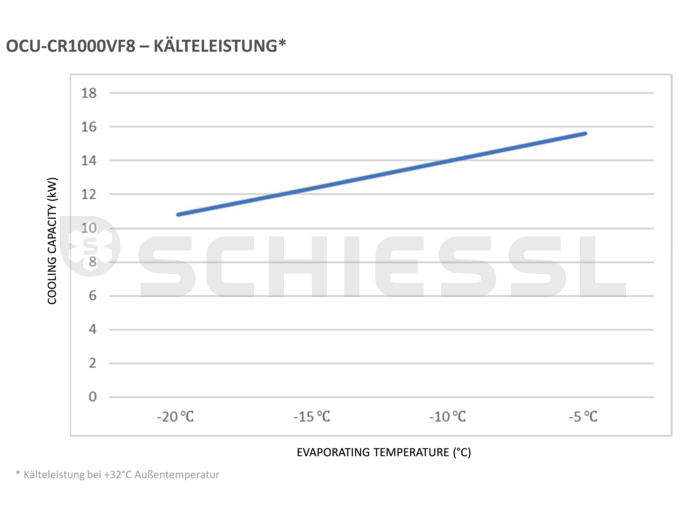

- Compact CO2 condensing units with 4 kW, 15 kW power ratings

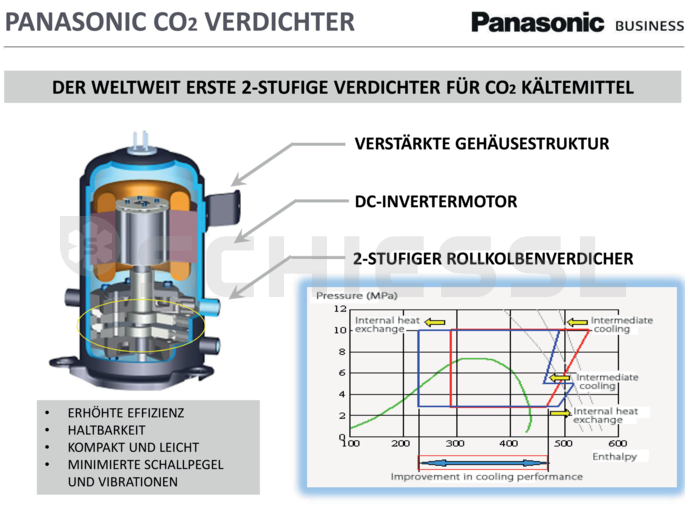

- Inverter-controlled, 2-stage rotary piston compressor

- Patented “SPLIT-CYCLE” technology

- Normal and low temperature applications with 4 kW condensing units (VT-45 / -5 °C)

- Normal cooling applications with 15 kW condensing units (VT-20 / -5 °C)

- Compact design and low weight

- Silent operation - max. 35.5 1)/36.0 2) dB(A) at 10 m

- Optionally with corrosion-resistant heat exchanger (SL)

- 4 kW devices also available as 1:n combination (max. 3 cooling locations) 3) see footnote

- With the 15 kW units it is generally possible to operate several evaporators4) see footnote

1) OCU-CR200VF5, OCU-CR1000VF8 / ET -10 °C, 65 S-1, at 10 m distance

2) OCU-CR200VF5SL / ET -10 °C, 60 S-1, at 10 m distance

3)Please note the following for 4 kW versions:

- The evaporating level for all cooling locations must be more or less the same (e.g. 1x -18 °C and 1x -6 °C does not work).

- 4 kW units in 1:n configurations are subject to the followingframework conditions:

- Panasonic checks all planned systems during the implementation phase (last amended 2019-03)

- Piping maximum must be observed

- Temperature specifications are observed

- 1:n: DT0 between all cooling locations =< 4 K

- Special features OCU-CR200VF5 (2HP unit)

- 1:n applications:

- 1:2 application:

- Both cooling locations are either refrigerators or air coolers

- No plate heat exchangers

- Difference in evaporating temperature between both locations must be no greater than 2 K

- Power and volume ratios should be around 40/60 or 60/40

- 1:3 application:

- Both cooling locations are either refrigerators or air coolers

- No evaporating temperatures below -15 °C

- No plate heat exchangers

- Evaporating temperatures in all locations the same

- Power and volume ratios should be around 35/35/30

- 1:4 and more: Not supported

- 1:1 implementation: - No further limitations

- 1:n applications:

- Fine tuning of combined devices is done during the initial setup.

4)Consider the following if using the 15 kW device (OCU-CR1000VF8):

- Number of cooling locations is theoretically unlimited, but in practice is around 10-12

- The smallest cooling location in the CO2 system when using the 15 kW device (OCU-CR1000VF8) should not have a power rating of less than 18%.

Scope of delivery

- Panasonic CO2 Verflüssigungssatz Invert. OCU-CR1000VF8 R744 400V

- 1x Panasonic CO2 filter dryer suction line S-008T - Artikelnummer: 758.2662

- 1x Parker filter dryer 2.0 CO2 CO-085-S (D-155T) 5/8" ODF - Artikelnummer: 251.280068

Accessories / Replacement parts

-

Adapter for safety valve

-

Cooling temperatures and superheating regulator with control panel, expansion valve (loose), pressure transducer and sensor set

-

Filter dryer

-

Intake pipe dryer

-

Kälteöl

-

Safety valve 80bar

-

Service connection (2 per unit necessary)

-

Service filling adapter

Technical data

.

design pressure FL=80bar

design pressure SL=80bar

1) 15 kW Standard condensing unit

2) 15 kW condensing unit with anti-corrosion coating