- Products

- Compressors & Assemblies

- Compressors

- Fully-hermetic

- Scroll

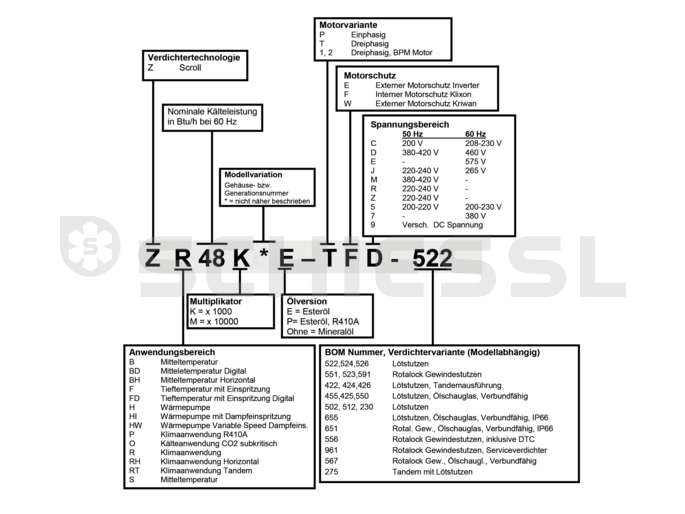

- Copeland fully hermetic scroll Compressor solder ZR18K5E-PFJ-622 230V

Copeland fully hermetic scroll Compressor solder ZR18K5E-PFJ-622 230V

Description

The Copeland ScrollTM compressor is the result of extensive research and development work that has been going on since 1979. This work has led to the production of the most advanced hermetic compressors currently available for air conditioning and heat pump applications in the 1.5 to 6.5 hp ...

The Copeland ScrollTM compressor is the result of extensive research and development work that has been going on since 1979. This work has led to the production of the most advanced hermetic compressors currently available for air conditioning and heat pump applications in the 1.5 to 6.5 hp range. The Copeland ScrollTM compressors are manufactured in state-of-the-art factories in Belgium and Northern Ireland.

Lubrication

Ester oil, factory filled: Emkarate RL 32 3MAF (531.2827, 1 litre can)

Refrigerants

approved for: R134a, R407C, R513A

Why scroll compressors?

System manufacturers prefer scroll compressors over other technologies for the following 4 reasons:

Economy, reliability, durability and low noise levels.

High-efficiency compressors

The coefficient of performance (COP) values achieve up to 3.37 W/W under ARI conditions. This never before achieved

power efficiency is the result of

- a very high volumetric efficiency under all approved operating conditions as the tips and surfaces of the spiral largely avoid any dead space and re-expansion (no tip seals, effective axial and radial adaptation)

- minimised pressure losses through the use of uniform high-speed compression with no valve plate

- reduced heat exchanger losses using improved separation of intake and pressurised gases.

Excellent noise emission values

The Copeland Compliant Scroll is the quietest compressor in its power range. The noise level is 6 dB lower than that of the hermetic piston compressors:

- Low operation noise as there are no pressure and intake valves

- Minimal vibrations and pulsations due to a gentle and continuous seal resulting from the lack of abrupt piston movements.

Extreme reliability

This has been achieved by:

- Fewer moving parts

- Tolerance for liquids and particulate contaminants that get sucked in

- Rigid installation of the internal compressor

- Low starting torque (unloaded start). A starting unit is not required for alternating current models.

- Internal self-resetting temperature and current-sensitive motor protection on models ZR18K* ... ZR81K*

- Protection against excessive pressurised gas temperatures (internal unit in models ZR18K* ... ZR81K*)

- The unique Compliance design means that the spiral surfaces adapt to each other and don’t become out of phase.

Accessories / Replacement parts

-

Adaptersatz Löt zu Rotalock

-

Crankcase heater

-

Refrigerator oil

-

Rotalock valves

Technical data

Note

- Compressors are delivered with an initial filling, The specified quantity is needed when refilling.

- Values are for the lowest rated voltage (50 Hz)

- Highest value in nominal voltage range

- auxiliary winding resistance / main winding resistance

- "L" = solder connection I.D.