- Products

- Compressors & Assemblies

- Compressors

- Fully-hermetic

- Scroll

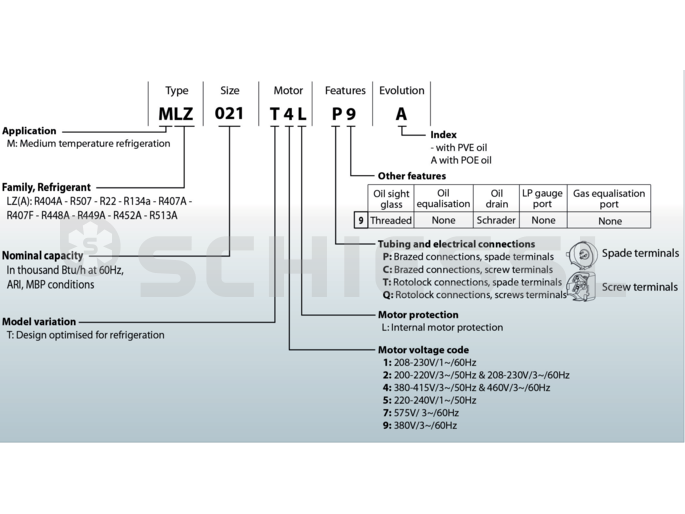

- Danfoss Scroll compressor MLZ021T5LP9 230V 121L8635

Danfoss Scroll compressor MLZ021T5LP9 230V 121L8635

Description

Designed for traditional refrigeration applications - MLZ refrigeration scroll compressors

Danfoss is a global supplier of high-quality and high-performance compressor solutions for refrigeration applications. From milk tanks and supermarkets through to cold storage rooms and ice machines – ...

Designed for traditional refrigeration applications - MLZ refrigeration scroll compressors

Danfoss is a global supplier of high-quality and high-performance compressor solutions for refrigeration applications. From milk tanks and supermarkets through to cold storage rooms and ice machines – we develop sustainable solutions that can meet the challenges of energy, environment and food safety facing our customers. The best example of this is our new MLZ range of scroll compressors that have been specially developed for the refrigeration technology sector.

Why so much emphasis on this aspect?

Simple: Refrigeration technology has its own special requirements. While air conditioning technology primarily aims to provide comfort, refrigeration technology focuses on process and food safety - areas that require a high degree of reliability. The evaporating temperature range and the operating conditions are two of the special challenges affecting the design of a refrigeration scroll compressor. The changing operating conditions, temperature spikes, the different number of evaporators, etc. presents a formidable challenge to using these scroll compressors. Fluctuating ambient temperatures also have an effect on operating conditions. It is for this reason that Danfoss developed the MLZ. This compressor delivers high energy-efficiency and reliability regardless of the application and operating conditions.

Low energy consumption

The combination of energy-efficient motor and scroll geometry specially optimised for refrigeration application achieves the ideal level of efficiency. A optimum constant axial pressure of the scrolls against one another is achieved using Danfoss’s patented adaptive control in a wide variety of system conditions (e.g. ice cream machines during the cooling phase). This avoids leaks as well as reducing friction to a minimum.

Long service life

The MLZ series of compressors has been specially designed for a long service life and reliability. This can be clearly seen in many details of the design details. For example, the “Oldham coupling” scroll guides are extra reinforced, especially high-quality carbon bearings for the crankshaft and a patented overload protection device (HOOP) protects the compressor from any damage caused by excessive loads.

Low noise operation

The design of the MLZ scroll compressor generates impressively low noise levels. The low friction, constant compression in the scroll set, the lack of intake and pressure valves, the perfect fit of the components and check valves optimised for the fluid mechanics of the system ensure exceptionally low noise and vibration-free operation.

Tailored solution

As wide and varied as refrigeration applications can be, the MLZ scroll compressor from Danfoss is always the right choice. MLZ compressors will make you clearly stand out from your competitors.

Scope of delivery

WICHTIG: Der Verdichter kommt ohne Anlaufvorrichtung!

PSC-Verkabelung mit nur einem Betriebskondensator ist die Standardverkabelungslösung für einphasige MLZ-Kompressoren. Die Startwicklung (C-S) des Motors bleibt über einen Dauerkondensator im Schaltkreis. Dieser Dauerkondensator ist ...

WICHTIG: Der Verdichter kommt ohne Anlaufvorrichtung!

PSC-Verkabelung mit nur einem Betriebskondensator ist die Standardverkabelungslösung für einphasige MLZ-Kompressoren. Die Startwicklung (C-S) des Motors bleibt über einen Dauerkondensator im Schaltkreis. Dieser Dauerkondensator ist zwischen der Startwicklung (S) und der Betriebswicklung (R) angeschlossen.

Die CSR-Verdrahtung sorgt für zusätzliches Motordrehmoment beim Start durch die Verwendung eines Startkondensators in Kombination mit dem Betriebskondensator. Der Startkondensator ist nur während des Startvorgangs angeschlossen, ein Potentialrelais trennt ihn nach der Startsequenz. Einige Anwendungen mit hohem Differenzdruck und Startbetrieb wie „Softeismaschine“ können eine CSR-Verdrahtung erfordern. Diese Konfiguration kann auch verwendet werden, um unregelmäßige Starts unter ungünstigen Bedingungen wie sehr niedriger Umgebungstemperatur oder schwacher Spannung zu reduzieren.

Accessories / Replacement parts

-

Adapter set

-

Anlassrelais

-

Crankcase heater

-

Mounting set

-

Operating capacitor

-

Pressurised gas temperature protection

-

Refrigerator oil

-

Rotalock valve, delivery side

-

Rotalock valve, intake side

-

Seal, delivery side

-

Seal, intake side

-

Sealing set

-

Shut-off valve

-

Solder sleeves, delivery side

-

Solder sleeves, intake side

-

Starting capacitor

Technical data

59,0 dB(A)

Erläuterung

- 2900 min-1 bei 50 Hz