A2L Refrigerant

A2L refrigerants are a category of refrigerants that are flammable, but less so than class A2 and A3 refrigerants. They are becoming increasingly important in refrigeration technology as their global warming potential is very low. A2L refrigerants also have low toxicity. If care is taken to use them correctly, they are safe and can be used over the long term. They are suitable for most components and systems.

Advantages of A2L refrigerants

The advantages of A2L refrigerants are manifold and particularly relevant in terms of environmental and safety aspects:

- Low global warming potential (GWP): A2L refrigerants such as R454C or R455A offer a reduction in GWP of up to 90% compared to conventional refrigerants. The GWP of HFO refrigerant R1234yf is even reduced by 99% compared to R134a.

- Low flammability: Although A2L refrigerants are flammable, their flammability is lower than that of class A2 and A3 refrigerants.

- No toxicity: Unlike refrigerants such as ammonia, A2L refrigerants are non-toxic and therefore easier to handle.

- Energy efficiency: A2L refrigerants are more energy efficient than R-410A and transcritical CO₂ systems

- Compatibility: Refrigeration systems can largely be realized with known components, pressure levels and systems, which facilitates the transition to A2L refrigerants.

These properties make A2L refrigerants an attractive option for the refrigeration industry, especially with regard to compliance with environmental regulations such as the EU F-Gas Regulation.

Why A2L refrigerants?

In order to reduce global warming, many countries have taken measures and issued regulations to reduce greenhouse gas emissions. The European Union's F-Gas Regulation will gradually reduce the amount of HFCs available on the market by 2050, until the complete phase-out from 2050. As synthetic refrigerants will continue to be needed, they must therefore have the lowest possible GWP value. A2L refrigerants are the right choice if alternatives such as natural refrigerants are not technically feasible. According to the resolution, the total available quota quantity of F-gases is to be reduced from 2023 to 74% in 2027 and 89% in 2030, in each case in relation to the 2023 quota. The chart shows a comparison of the resolutions from 2015 and 2023.

|

The industry has developed new refrigerants, so-called hydrofluoroolefins (HFOs), which have a significantly lower GWP value than conventional HFC refrigerants and can be used without major modifications to systems. HFO refrigerants such as R452A and R449A are now the industry standard and help to reduce greenhouse gas emissions, but do not meet the future GWP requirements of less than 150.

As there are currently no non-flammable alternatives with a GWP below 150, the refrigeration industry will have to fall back on flammable refrigerants. Natural refrigerants are not always a suitable alternative due to their properties. The industry will therefore have to deal with flammable HFO refrigerants.

Safety classes of refrigerants

Although A2L refrigerants are flammable, they are less so than class A2 and A3 refrigerants. When handled correctly, they offer a safe and long-term option for installations, components and systems. The HFO and HFO-based mixtures currently in use are classified as A2L safety class.

A2L Webinar - Opteon / SCHIESSL

Here you will find a recording of a webinar with lots of information about A2L refrigerants.

Our A2L product range

Discover our wide range of high-quality refrigeration sets, outdoor units, evaporators and system components that can be operated with A2L refrigerant.

Refrigeration sets A2L

Outdoor units A2L

Evaporators A2L

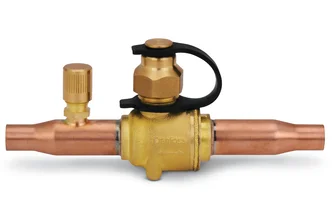

System components A2L

Refrigerants A2L

Questions and answers about A2L refrigerants

For which systems is A2L refrigerant suitable?

As these refrigerants fall into class A2L, they may only be used in systems that are specially designed for these refrigerants and consist of A2L-compatible components. The application must also comply with the relevant standards. Safety standards such as EN 378 define the necessary safety measures. Many factors determine the extent of the safety precautions. Additional safety measures should be taken as the size of the system increases. A2L refrigerants are therefore particularly suitable for small and medium-sized systems in commercial refrigeration and for indirect systems with larger capacities.

What must be observed when handling A2L refrigerant cylinders?

-

Always handle refrigerant cylinders with care! Protect them from moisture and rust and do not store them near incompatible materials or flammable substances. Avoid mechanical damage by handling them properly and do not force open the valves.

-

Always keep the bottles below 52°C to avoid exceeding the maximum pressure. Do not use open flames to heat refrigerant cylinders and never exceed this temperature limit.

-

Only use recycled cylinders that are suitable for A2L refrigerants and pay strict attention to the maximum filling weight. Do not fill reusable refrigerant cylinders with refrigerant that has already been used.

-

The refrigerant should only be removed from the cylinder in liquid form. It can then be introduced into the refrigeration system in either liquid or gaseous form.

Is soldering on A2L refrigeration systems dangerous?

- The following safety measures should be taken when soldering:

- Check that the concentrations of refrigerant and oxygen in the air are safe.

- Secure your work area and ensure that it is well ventilated. - If possible, remove the lubricant in the area of the soldering or welding point to prevent fires.

- Siphon off the refrigerant into suitable A2L recycling bottles and prevent it from entering the ambient air.

- If necessary, flush the system with nitrogen. Otherwise, open the system and ensure that there is no residual pressure.

- Leave the system open during work to prevent pressure build-up.

- Provide additional ventilation to disperse smoke or refrigerant residue during the repair. If the size, shape or color of the open flame changes significantly, this indicates a high refrigerant concentration. Stop all work immediately and ensure thorough ventilation.

What tools and equipment are required to maintain A2L systems?

Most tools that are used for A1 refrigerants are also suitable for A2L refrigerants. However, equipment such as extraction stations and vacuum pumps must comply with the relevant regulations. Due to their electrical components and motors, they must be specially designed for use with A2L refrigerants, which are difficult to ignite.

Is a leak of A2L refrigerant dangerous?

If you notice a leak, act as follows:

Only re-enter the area where the refrigerant has leaked once the vapors have completely dissipated or you are wearing suitable respiratory equipment. No one should remain there until the area is sufficiently ventilated. To improve air circulation directly above the floor or in lower areas, use fans or blowers.

What should I bear in mind regarding the filling quantities of A2L refrigerant?

The ISO 5149 and EN 378 standards specify the refrigerant charge based on flammability class, lower flammability limit (LFL) and room size. There are also minimum charge quantities without room-related restrictions.

For class 2 and 3 refrigerants, the maximum charge is less than 4 x LFL, regardless of the room size. For class 2L, up to 6 x LFL is permitted. Due to the higher LFL value of 2L refrigerants, larger charge quantities are possible without room-related restrictions (e.g. R1234yf - 1.73 kg) compared to A3 refrigerants (e.g. R290 - 0.15 kg). If the filling quantities are larger, the size of the room must be taken into account. Further protective measures must then be taken.