- Products

- Evaporators & condensers

- Condensers

- Water-cooled

- Shell & Tube condensers

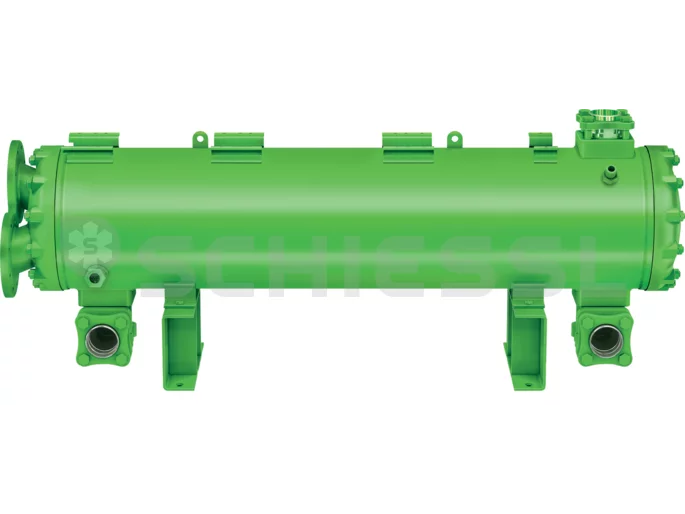

- Bitzer shell-and-tube condenser seawater K1353TB-2 pass connection for cooling tower

Bitzer shell-and-tube condenser seawater K1353TB-2 pass connection for cooling tower

More in this category: Shell & Tube condensers

One click to the most important information:

Description

The water-cooled pipe bundle condensers from BITZER have long represented a standard in the refrigeration and air conditioning technology due to their well-known reliability and performance. The K series consists of two different versions to meet the demands of a wide variety of different ...

The water-cooled pipe bundle condensers from BITZER have long represented a standard in the refrigeration and air conditioning technology due to their well-known reliability and performance. The K series consists of two different versions to meet the demands of a wide variety of different applications. The unique soldering process used to connect the pipes and pipe bases provides excellent stability against vibrations and secure seals.

New models

The new model K6703.(B) and K8503.() enhance condenser performance of the standard and salt water resistant versions in the range above 1000 kW.

Standard version for normal water

The heat transfer pipes stand out for their high strength, the pipe bases are plastic-coated. This series is suitable for all coolant types that do not react with copper.

Salt water resistant version

The K..B models have been tried and tested over many decades in all kinds of maritime applications. They are extremely resistant to sea water corrosion. The low fouling profile pipes as well the plastic coating on the pipe bases and cooling medium recirculation caps make this a top choice. Liquid refrigerants flow out through an immersion pipe outlet on models up to K813HB and through two refrigerant outlets on models K1053HB and above.

Pressurised gas heater

Sizes K1053H to K4803T can also be supplied in the standard version for normal water as a pressurised gas heater. The optional second refrigerant outlet must be ordered in this case.

Features

Maximum permitted pressure

- Refrigerant side: 33 bar / -10 to 120 °C

- Cooling medium side: 10 bar / -10 to 95 °C

Temperatures below 4 °C require an antifreeze agent

This data applies for CE certification according to the EU Pressure Equipment Directive. Figures may vary depending on the ...

Maximum permitted pressure

- Refrigerant side: 33 bar / -10 to 120 °C

- Cooling medium side: 10 bar / -10 to 95 °C

Temperatures below 4 °C require an antifreeze agent

This data applies for CE certification according to the EU Pressure Equipment Directive. Figures may vary depending on the certification process. Suitable for all conventional refrigerant and cooling media

Refrigerant side

- high-performance pipes with external ribbing

- Refrigerant connections: Pipe with thread or flange

- Inlet:

to K813H(B), Rotalock adapter

solder connector with flange K1053H(B) and above

- Outlet: Shut-off valve

- various optional adapter and valve combinations

- pressured gas heater - special version:

Connection for second refrigerant outlet available on K1053H to K4803T - Connection for pressure relief valve:

- Inner thread: 3/8-18 NPTF

- Outer thread: 1 1/4-12 UNF

- various optional adapters - inspection glass with deflection gratings as standard

Cooling medium side

- Pipes with inner low fouling profile

- Cooling medium connections: Pipe with thread or flange

- Cooling medium drain from K573H(B)

- Additional bleed plugs with models from K3803T(B)

Inert gas filling

- 0.2 .. 0.5 bar nitrogen

Sturdy construction for simple maintenance

- Secure seals: Heat transfer pipes are soldered into the pipe bases.

- Easy to clean: both cooling medium recirculation caps are removable

- Flexible: Cooling medium recirculation cap connection and deflection sides are interchangeable

- Mounting brackets

- Mounting brackets on bottom for stable support

- Types H and T: additional mounting brackets on top saves space when mounting the compressor

- Perfectly sized mounting plates and rails optionally available

Materials

- Heat transfer pipes

- Standard version: Copper (ISO code Cu-DHP; UNS code C12200)

- Salt water resistant version: Copper-nickel 90/10 (ISO code CuNi10Fe1Mn; UNS code C70600) - Casing pipe: Carbon steel P265GH

- Pipe bases: Carbon steel P265GH, plastic-coated

- Cooling media recirculation caps: Cast iron EN-GJL-250 or carbon steel P265GH, plastic-coated on salt water resistant version

Technical data

(see explanation 4)

Notes

- Performance data based on:

Refrigerant: R134a

2-pass cooling

Refrigerant inlet temperature: 90°C

Cleanliness factor on cooling medium side: 0,00004 m²K/W

Standard design

Condensation temperature: 40°C

Cooling medium inlet temperature: 29°C

Sea water resistant version

Condensation temperature: 35°C

Cooling medium inlet temperature: 25°C

The condenser performance is very strongly influenced by the system operating conditions. For performance data for other refrigerants and cooling media, see BITZER SOFTWARE. - This information takes into account a maximum flow velocity of 2.0 m/s for the seawater-resistant versions.

- At 20°C liquid temperature and 90% tank content

- Additional refrigerant

Type K033NB

K073HBK123HB

K203HBK173HB

K573HB

K813HB

K1053H*

K1053HB

K1353T*

K1353TBK1973T*

K1973TBK2923T*

K2923TBK3803T*

K3803TB

K4803T*

K4803TBK6703TB

K8503TBAdditional

Refrigerant outlet- 11/4-12UNF 13/4-12UNF 21/4-12UNF DN50 DN80 DN80

*Special version

For welding neck DIN2633, ND 10/16 or threaded flange DIN2566, ND 10/16

For individual performance data, see BITZER SOFTWARE