- Products

- Evaporators & condensers

- Condensers

- Water-cooled

- Shell & Tube condensers

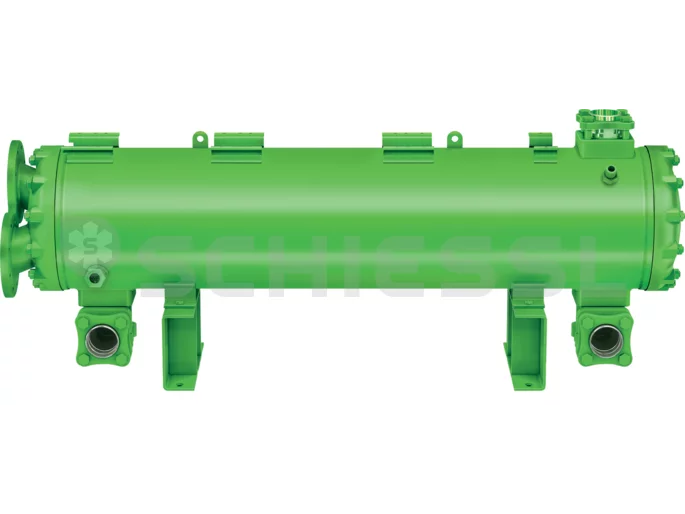

- Bitzer shell-and-tube condenser K123H-2/4 pass connection for city water

Bitzer shell-and-tube condenser K123H-2/4 pass connection for city water

More in this category: Shell & Tube condensers

One click to the most important information:

Description

Design safety

Certified according to the European Pressure Equipment Directive 2014/68/EU

Design features

- Heat exchanger pipes: made from Cu or Cu-Ni (saltwater resistant version) with newly developed pipe geometry and a “low foulin

- g” profile on the cooling medium side

- Heat exchanger pipes ...

Design safety

Certified according to the European Pressure Equipment Directive 2014/68/EU

Design features

- Heat exchanger pipes: made from Cu or Cu-Ni (saltwater resistant version) with newly developed pipe geometry and a “low foulin

- g” profile on the cooling medium side

- Heat exchanger pipes are soldered into breaker plates to ensure a secure seal

- mantle pipes and breaker plates made from pressure vessel steel P 265 GH

- Recirculating cap:

- removable, allows pipes to be mechanically cleaned

- connection and deflecting side interchangeable

- cooling medium outlet from K573H(B)

- additional bleeding plugs from K38 03T(B) - Breaker plates with plastic coating

- Cooling medium connections: Threaded pipe or flange

- inspection glass as standard

- Mounting brackets

- bottom: vessel labelled as “N”

- top and bottom: vessel labelled as “H” (for installing single compressors) and “T” (for single and tandem compressors) - Refrigerant connections

- pressurised gas: Rotalock adapter/solder connector with flange K1053H(B) and above

- refrigerant outlet: shut-off valve

- alternative refrigerant outlet from model K123HB - Rotalock connections for pressure relief valve

- inner thread 3/a'' -18 NPTF

- outer thread 1 ¼” - 12 UNF - suitable for (H)CFC / HFC refrigerants (refrigerants with a temperature glide > 2 K on request)

- Maximum permitted pressure/temperature

- refrigerant side: 28 bar / -10 °C to 120 °C

- cooling medium side: 10 bar / -10 °C (with antifreeze agent) to 95 °C - inert gas filling

bundled pipe condensers with refrigerant outlet at the bottom can also be used as pressurised gas desuperheaters.

Special versions:

- Salt water resistant version:

- Cu-Ni pipe, recirculating cap with plastic coating - recirculating cap with plastic coating for standard version with Cu pipes

- mounting rails or plates (e.g. for installing compressor)

- adapter for connecting the pressure relief valve on all models

- threaded or welding neck flange

- refrigerant inlet and outlet with various adapter and valve combinations

- conforms to foreign regulations and various certification societies (e.g. Bureau Veritas, Germanischer Lloyd, Lloyd's Register of Shipping)

Scope of delivery / accessories

4-pass design corresponds to standard version

Performance data

The specified compressor performance is based on valves measured at a pressurised gas temperature of 90 °C and a cooling medium cleanliness factor r= 0.4 x 1 o-4 m2 K/W.

Condenser design

Calculating of condenser capacity Q

When selecting a condenser it is first necessary to determine the condenser capacity Q. Condensing capacity can be calculated in two different ways:

Condensing capacity as the sum of the refrigeration capacity and power consumption

This method adds together the refrigeration capacity and power consumption of the compressor (or compressors in a power rack). Performance data can be found in the compressor information leaflets or in the software.

Estimation using factors

A simplified method can also be employed for typical designs. To determine condensing capacity, the refrigeration capacity of the compressor is multiplied by the factor in the following diagram.

Important note

For low temperature applications in particularly, the condenser must be sufficiently powerful such that there is a sufficient reserve of power for cooling off processes or de-icing periods (control calculation at highest evaporating temperature necessary).

Accessories / Replacement parts

-

Adapter

-

Rail set bottom

-

Rail set top

-

Upper mounting plate

Technical data

(see explanation 4)

Notes

- Performance data based on:

Refrigerant: R134a

2-pass cooling

Refrigerant inlet temperature: 90°C

Cleanliness factor on cooling medium side: 0,00004 m²K/W

Standard design

Condensation temperature: 40°C

Cooling medium inlet temperature: 29°C

Sea water resistant version

Condensation temperature: 35°C

Cooling medium inlet temperature: 25°C

The condenser performance is very strongly influenced by the system operating conditions. For performance data for other refrigerants and cooling media, see BITZER SOFTWARE. - This information takes into account a maximum flow velocity of 2.0 m/s for the seawater-resistant versions.

- At 20°C liquid temperature and 90% tank content

- Additional refrigerant

Type K033NB

K073HBK123HB

K203HBK173HB

K573HB

K813HB

K1053H*

K1053HB

K1353T*

K1353TBK1973T*

K1973TBK2923T*

K2923TBK3803T*

K3803TB

K4803T*

K4803TBK6703TB

K8503TBAdditional

Refrigerant outlet- 11/4-12UNF 13/4-12UNF 21/4-12UNF DN50 DN80 DN80

*Special version

For welding neck DIN2633, ND 10/16 or threaded flange DIN2566, ND 10/16

For individual performance data, see BITZER SOFTWARE